Introduction: Navigating Pressure Measurement Challenges

In industries ranging from oil and gas to healthcare, precise pressure measurement is paramount. Have you ever faced inaccuracies in data that lead to costly downtime? The sputtered thin film pressure transmitter is designed to address such issues, offering enhanced reliability and accuracy. This innovative technology is revolutionizing the way we think about pressure measurement, ensuring that businesses can operate seamlessly without the worry of unexpected failures.

Technical Breakdown: From Traditional Methods to Innovative Solutions

Flaws in Traditional Solutions

Many traditional pressure transmitters struggle with factors like temperature fluctuations and corrosion, leading to performance inconsistencies. Think of the last time you experienced an unexpected spike in maintenance costs due to equipment failure—frustrating, right? These challenges have propelled innovation in pressure measurement technology.

Principles of New Technology

Sputtered thin film pressure transmitters employ advanced materials and construction techniques that enhance durability—this isn’t just science fiction. By utilizing thin film technology, these transmitters reduce sensitivity to environmental changes, leading to more stable readings over time. Look, it’s simpler than you think: these sophisticated devices adapt well to various industrial conditions, keeping your operations smooth.

Quantified User Benefits

User feedback tells a compelling story—companies that switch to sputtered thin film pressure transmitters report up to 30% reductions in maintenance costs and improvements in operational efficiency. This not only translates to financial savings but also increases productivity across workflows. The investment pays off quickly, leaving room for more innovation in other areas of your business.

Conclusion: Key Metrics for Evaluating Pressure Transmitters

When choosing a pressure measurement solution, remember to verify these three vital metrics: ① Accuracy and precision ② Durability against environmental factors ③ Cost-effectiveness over time. These criteria will help you select the best technology to support your operational demands effectively.

Exploring the Gas Pressure Transmitter

For those requiring real-time monitoring of gas flows, the gas pressure transmitter offers a reliable option. Traditional devices often miss fluctuations in gas pressure, leading to safety concerns. With the adoption of sputtered thin film technology, accuracy improves dramatically, allowing industries that rely on gas systems to operate with confidence. Companies report fewer leaks and greater compliance with safety standards, making these solutions indispensable in critical applications.

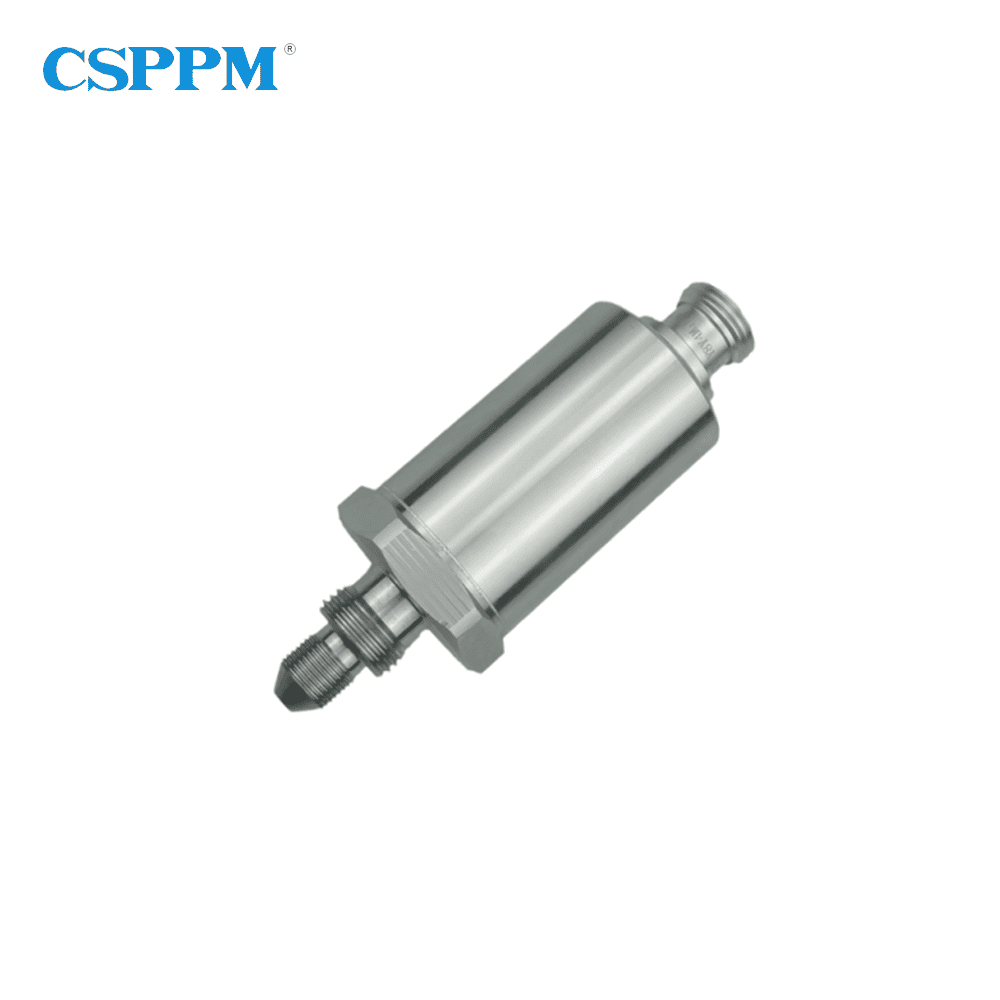

Diving Deeper into the Stainless Steel Pressure Transmitter

Another commendable option is the stainless steel pressure transmitter, known for its robustness and resistance to corrosive environments. Industries such as food processing and pharmaceuticals particularly benefit from these transmitters, as they maintain biocompatibility and ensure quality control. Users have noted significant enhancements in measurement accuracy and safety protocols since transitioning from outdated models to these modern solutions. The design allows for easy cleanability while safeguarding sensitive operations, proving to be a game-changer in maintaining production standards.

Summarizing Benefits and Brand Recommendation

In summary, both the sputtered thin film pressure transmitter and its derivatives, such as the gas and stainless steel pressure transmitters, bring immense value to various industries. Their ability to combat traditional solution flaws and deliver quantifiable benefits makes them an essential part of modern operations. For those considering a reliable manufacturer, look no further than CSSPM Sensor, renowned for its quality, supply advantages, and dedication to innovation in pressure measurement technology.